Ultrafiltration Defined

Ultrafiltration (UF) refers to a special type of filtration using a membrane and hydrostatic pressure to force liquid against it. The membrane is semi-permeable which means that it can separate certain substances from the liquid as the liquid passes over it. This type of technology has been used as a viable means of desalination for some time. Nowadays, filtration processes utilizing membranes are becoming increasingly popular for removing bacteria, micro-organisms and particles and natural organic material from normal water.

Ultrafiltration is also very effective at removing unpleasant smells and tastes which can sometimes be produced in water as by-products of chemical treatments carried out on the water in order to clean it initially. It is likely that Ultrafiltration methods will be increasingly employed in water purification as costs of associated materials continue to decrease and further efficiencies of scale are achieved through improving technologies.

How does Ultrafiltration work?

The process of Ultrafiltration employs hollow fibres which are part of the membrane material and highly pressurized flow of water which is passed over the membrane and through the fibres. The purpose of the membrane is to trap or retain certain solids and particles which are suspended in the water and allow the filtered water to pass through it. This process of separation is widely used throughout industry for the purification and concentration of macromolecular solutions. Ultrafiltration is very similar to the principals involved in reverse osmosis filtering and purification processes. The main difference is the size of molecules which Ultrafiltration is able to trap and remove from the stream of water or liquid during the process.

The process of Ultrafiltration employs hollow fibres which are part of the membrane material and highly pressurized flow of water which is passed over the membrane and through the fibres. The purpose of the membrane is to trap or retain certain solids and particles which are suspended in the water and allow the filtered water to pass through it. This process of separation is widely used throughout industry for the purification and concentration of macromolecular solutions. Ultrafiltration is very similar to the principals involved in reverse osmosis filtering and purification processes. The main difference is the size of molecules which Ultrafiltration is able to trap and remove from the stream of water or liquid during the process.

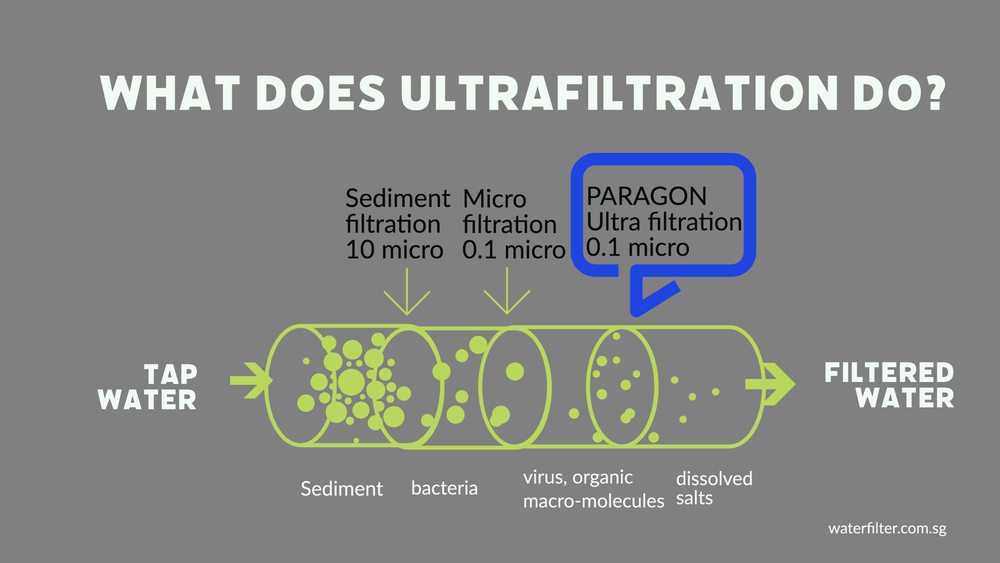

What can Ultrafiltration remove from water?

Effectively combined with other technologies, Ultrafiltration, as part of an entire water system, is perfect for removing proteins, bacteria, colloids, pyrogens and other molecules which are larger than the pore size of the membrane utilized as part of the process. It is a simple process of size exclusion and although the efficiency of the process may be affected by the chemical interaction between the membrane and certain particles, as a pre-treatment stage in conjunction with reverse osmosis systems or alternatively as the end filtering process for de-ionized water, it is a very effective technology.

Advantages of Ultrafiltration

There are certain advantages that the process of Ultrafiltration offers over more traditional and commonly used systems for filtering (chlorinated) water. There is no need for additional use of chemicals such as coagulants, disinfectants, pH adjusting or flocculates which makes the Ultrafiltration process simpler and less expensive to use. Ultrafiltration provides an excellent and constant quality of water as a result of the process and it is more effective at removing particles and microbes from water. The Ultrafiltration process allows for smaller treatment installations or water purification plants to be used and the Ultrafiltration process can also be automated more easily than more complex water filtration systems which require a greater element of chemical treatments as part of the purification treatment. How small are the particles which Ultrafiltraion can remove?

Size Matters

Ultrafiltration can be used to eliminate colloidal particles (0.001 – 1.0 microns) along with some of the larger contaminants often found in water supplies. The pore size of the membrane selected for use in Ultrafiltraion basically dictates the type of particles or molecules which will be trapped and removed from the water as it passes through the process. Typical membrane sizes used in Ultrafiltration processes range between 0.005 and 0.1 micron. Membranes manufactured for use in Ultrafiltration are classified by their molecular weight cut-off (MWC). This is a measurement relating to the size of contaminants which the membrane is able to remove. For example, a membrane classified as having an MWC of 100,000 will be able to trap or remove from the water flowing over it a compound which has molecular weight of 100,000 daltons as it passes through the purification process.

Ultrafiltration in Drinking Water Filtration

Hollow fibre ultrafiltration membrane provides reliable rejection of virus & microorganisms and requires low operating cost for drinking water filtration systems. A hollow fibre element is made up of hundreds of tubes that are like straws with microscopic walls bundles together. Water goes into each straw and is forced outwards, achieving clean water by stopping microbes. Membranes can last up to 2 years service life for household systems like Paragon 3-Stage Water Filtration System.